A critical aspect of safety when it comes to materials science and engineering is the understanding of how materials behave when exposed to fire.

This Is where the UL 94 standard comes into play. UL 94, the Standard for Safety of Flammability of Plastic Materials for Parts in Devices and Appliances, is a worldwide recognized standard that evaluates the flammability of plastic materials.

What is UL 94?

UL 94 is a plastics flammability standard released by Underwriters Laboratories (UL) in the United States. It determines the material’s tendency to extinguish or spread the flame once the specimen is ignited. It is a collection of different test methods to evaluate the flammability of plastic materials based on the construction of the material being tested. Sample types can include injection mold parts, thin films, or foamed materials, among others. The standard includes small-scale tests that evaluate the flammability of polymeric (plastic) materials used for parts in devices and appliances in response to a small, open flame or radiant heat source under controlled laboratory conditions.

What Do UL 94 Certifications Mean?

UL 94 certifications provide a method for rating the ignition characteristics of plastic materials. These ratings ensure that materials used in various applications meet specific safety standards. The certifications empower manufacturers, engineers, and designers to choose the right materials for their products.

Different UL 94 Ratings

The UL 94 standard includes several ratings, each indicating a different level of flammability resistance. The primary ratings include:

| Rating | Description | Examples |

| HB (Horizontal Burning) | Materials burn slowly across the sample when the test flame is applied to the end of the horizontal sample. | Polycarbonate (PC), Acrylonitrile Butadiene Styrene (ABS) |

| V-0, V-1, V-2 (Vertical Burning) | These ratings are for materials tested in a vertical position. V-0 is the highest, followed by V-1 and V-2. Test criteria include after flame time, not burn to the top clamp, and whether the material drips and ignites a cotton indicator. | Polyphenylene Sulfide (PPS) with 40% glass fiber reinforcement (HiFill® PPS/F GF40) – V-0; Polycarbonate (PC) – V-2; |

| VTM-0, VTM-1, VTM-2 (vertical burning for very thin film) | These ratings are for materials tested in a vertical position. V-0 is the highest, followed by V-1 and V-2. Test criteria include after flame time, not burn to the top clamp, and whether the material drips and ignites a cotton indicator. This is for material less than 0.25 mm in thickness | Flame retardant PE, PP |

| HBF, HF-1, and HF-2 | These ratings are for foamed materials in devices and non-structural applications. The test criteria here is on burning rate (similar to HB), after flame, and igniting a cotton indicator | PE foam |

| 5VA and 5VB | These are the most stringent ratings. Materials with a 5VA rating do not burn with a flame after five applications of five seconds each of a flame. Materials with a 5VB rating may have a burn-through (a hole) in the specimen. | Polyether Ether Ketone (PEEK), Polyphenylsulfone (PPSU) – 5VA; |

The UL 94 Testing Process

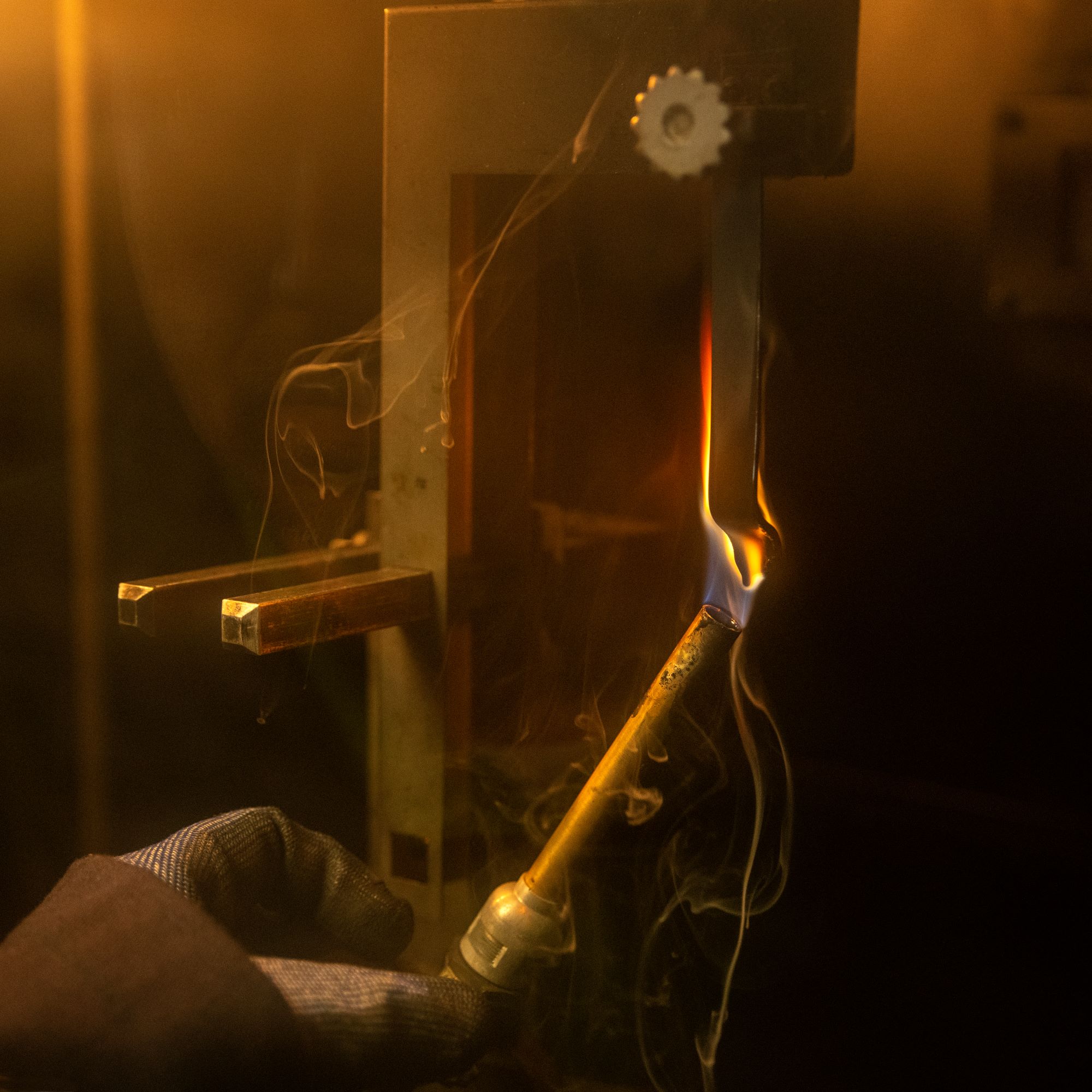

The UL 94 testing process, a comprehensive evaluation of the flammability characteristics of plastic materials, involves several meticulous steps.

- Sample Preparation: The material samples are prepared according to specific dimensions and conditioning requirements. For example, samples may be conditioned at 23°C (±2°) and 50% RH (±5%) for a minimum of 48 hours.

- Horizontal Burning Test (HB/HBF): The sample is placed horizontally, and a flame is applied to one end. The time it takes for the flame to travel a specific distance is measured. The burning rate is calculated based on the distance burned and the time taken.

- Vertical Burning Test (V and VTM): For vertical burning tests, the sample is placed vertically, and a flame is applied to the bottom. The after-flame time (time the sample continues to burn after the flame is removed) and afterglow time (time the sample continues to glow after the flame is removed) are measured. The presence of flaming drips that ignite a cotton indicator is also noted.

- 5VA and 5VB Tests: These tests involve applying a flame to the sample for five applications of five seconds each. The material’s ability to self-extinguish and resist burn-through is evaluated. The 5VA rating requires no burn-through, while the 5VB rating allows for burn-through.

- Final Classification: Based on the test results and the type of material in the sample, the material is classified according to UL 94 ratings.

Effects of Flammability

Flammability measures how quickly a material can catch fire when exposed to ignition. It is influenced by several factors, including the chemical composition of the material, the presence of additives, and the conditions under which the material is exposed to heat or flame. Understanding the flammability of materials is crucial for ensuring safety in various applications, from consumer electronics to automotive components.

Specific Applications of Materials with UL 94 Ratings

Materials with different UL 94 ratings are used in various applications based on their flammability resistance:

| Test Type | Applications |

| HB (Horizontal Burning) | Consumer electronics housing, automotive interior parts, household appliances |

| V-0, V-1, V-2 (Vertical Burning) | Electrical enclosures, connectors, components in automotive and aerospace industries |

| 5VA and 5VB | Medical devices, high-performance electrical components, critical aerospace parts |

How Techmer PM Can Help

Techmer PM is a materials design company specializing in tailoring the properties of polymers. We thrive in partnership with plastics processors, OEMs, and designers to solve complex business, manufacturing, and sustainability challenges by leveraging our leading-edge technologies. When it comes to UL 94 and flammability standards, we offer:

- Flame-Retardant masterbatches and compounds formulations: Techmer PM formulates, tests, and produces flame-retardant (FR) compounds critical to the safety of many components that have moved to plastic over the years. Our expertise spans from EVA to PEEK, using various FR technologies.

- Techmer has a range of UL yellowcards and can work with the UL regulatory group to generate new cards for existing or new applications.

- Combinations of FR with other additives: We specialize in combining FR with fiber reinforcement, colors, UV stabilizers, and other additives to meet specific application requirements.

- Testing and Certification: Techmer PM can perform various flame tests, including UL 94, NFPA 701, and ASTM D6413, ensuring our products meet the highest safety standards.

- Customized solutions: We work closely with our customers to develop customized solutions that meet their unique needs, whether achieving a specific UL 94 rating or addressing other performance criteria.

Understanding UL 94 and its certifications is important for ensuring the safety and performance of plastic materials in various applications. With its extensive flame-retardant formulations and testing expertise, Techmer PM is well-equipped to help you navigate these standards and achieve your safety goals.

If you need help with a product challenge, email globalmarketing@techmerpm.com for more information.